Weekly septic loads now tracked in real time

Of trips now scheduled using live tank data

Data and alarm updates from every site

Real-time visibility of septic tanks is helping SA Water reduce truck rolls, prevent overflows and improve wastewater outcomes.

The Need

Across South Australia, septic systems traditionally relied on manual inspection. Technicians would drive to remote sites, lift heavy lids and make visual checks to see if tanks needed emptying. It was time-consuming, reactive, and prone to error. Missed timings meant spills. Early visits wasted resources.

To fix this, SA Water partnered with Kallipr on a project to automate septic tank monitoring across its network using real-time IoT sensing.

The Challenge

As South Australia’s wastewater network expanded, manual inspections became unsustainable. With 50 tanks across the state and around 130 loads per week, SA Water needed a smarter way to plan tank operations.

“Visual indicators worked when there were only a few tankering transactions each day,” said Shannon Uern, SA Water’s Manager of Wastewater Planning. “But as volumes increased, we needed far more accurate intelligence to avoid running right up to the spill point.”

Earlier attempts using other measurement instruments struggled with harsh conditions or cost overheads. What SA Water wanted was a reliable, affordable and low-maintenance solution that could deliver millimeter-accurate level readings without the infrastructure demands of SCADA.

The Solution

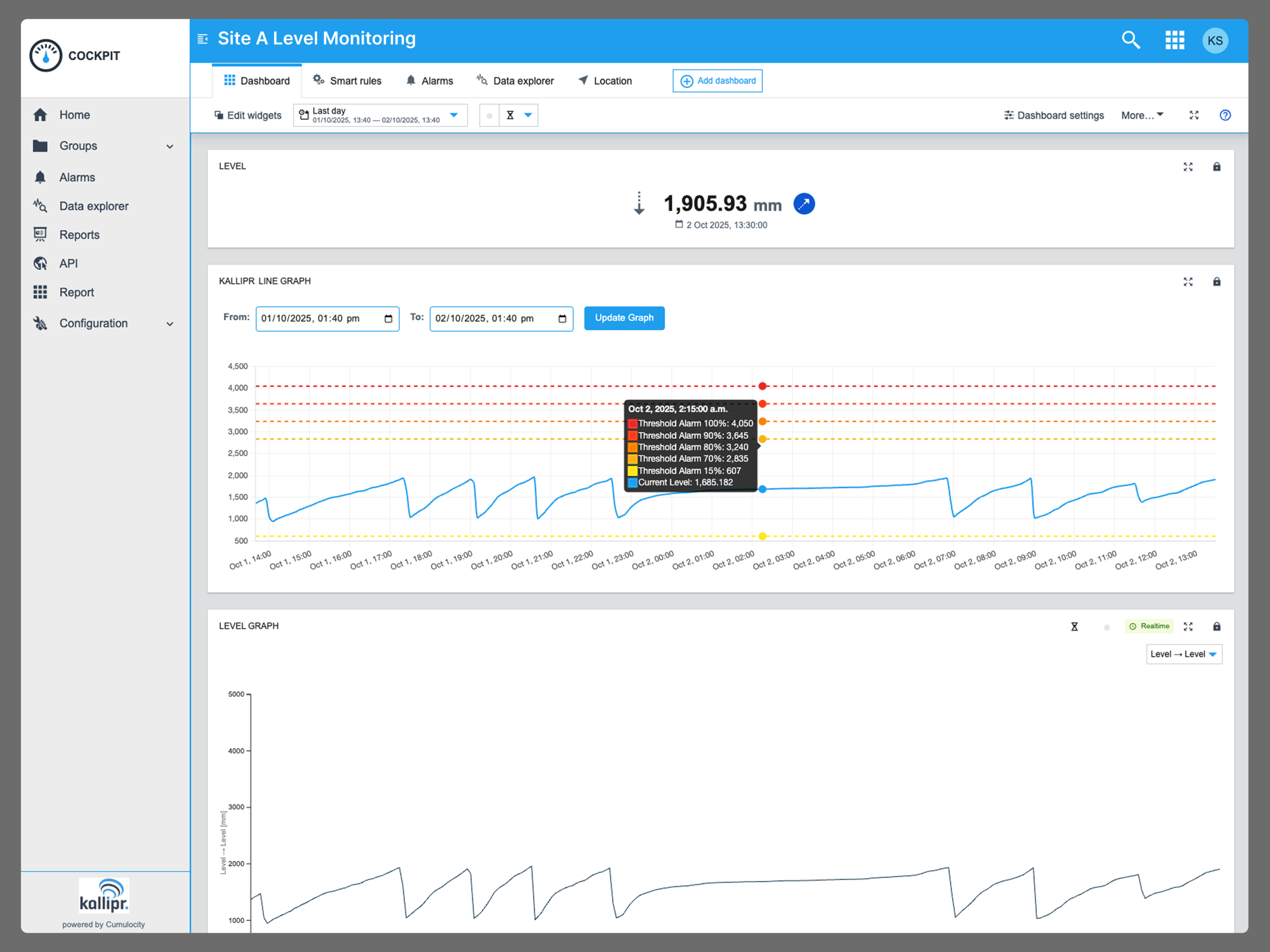

SA Water deployed Kallipr’s Captis Recharge telemetry unit paired with radar level sensors in each septic tank. The sensors measure liquid depth every five minutes, while the Captis device transmits aggregated data to the cloud every 15 minutes via cellular networks.

A compact solar panel powers the system, making it ideal for remote or portable sites. The data appears in Kallipr Kloud, Kallipr’s secure cloud platform, giving both operations staff and haulage contractors real-time visibility of every tank.

“Because the data refresh is so frequent, we used a small solar panel to power the unit,” said Stelios Trikoulis, Chief Commercial Officer at Kallipr. “The form factor makes it easy to install without major infrastructure.”

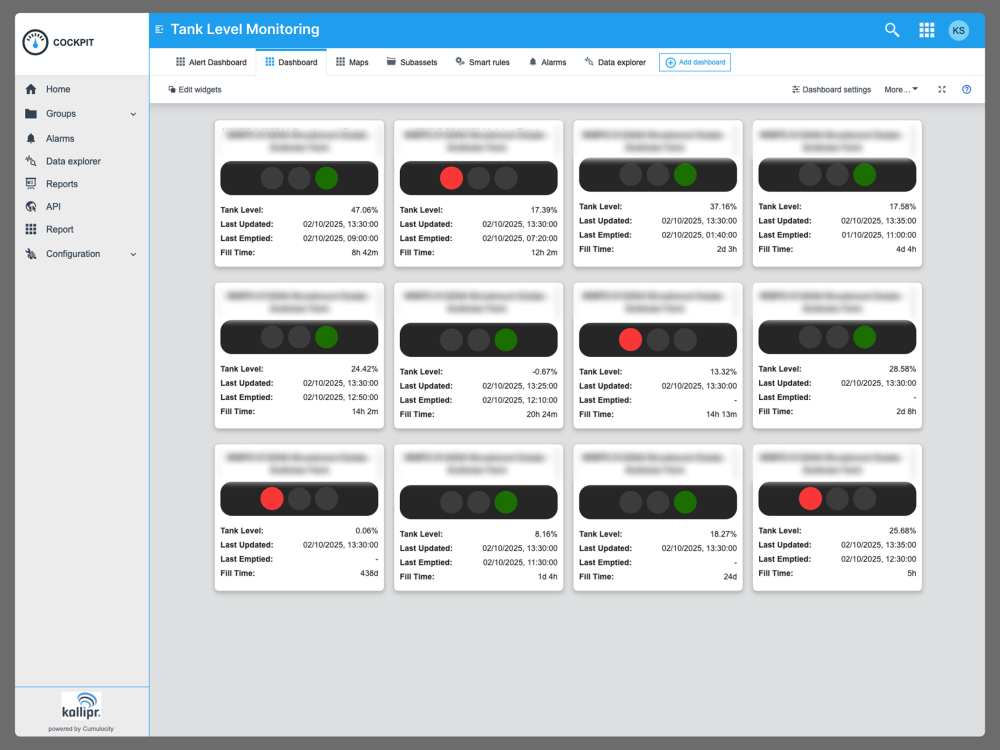

Within the platform, a traffic-light dashboard simplifies decision-making – green for fine, orange for alert, red for full – allowing haulers to send the right truck, at the right time, to the right place.

The Results

The rollout immediately improved efficiency across SA Water’s septic operations:

- No overflows: Early alerts allow teams to act before tanks reach spill point

- Fewer truck call outs: Real-time data replaces routine callouts and unnecessary trips.

- Lower operating costs: Optimised scheduling and reduced fuel, labour and vehicle wear.

- Early issue detection: Data reveals infiltration, leaks and pump faults before they escalate.

- Better planning: Portable devices make expansion simple as new developments come online.

“It gives our haulers the intelligence they need, reduces wasted effort, and provides us with valuable insights we never had before,” said Uern.

The benefits extend beyond scheduling. Continuous monitoring has revealed previously hidden problems from stormwater intrusion to customer leaks, helping SA Water act earlier and protect downstream assets.

The Bigger Picture

What started as a targeted fix for septic tanks is now part of SA Water’s wider smart network strategy, integrating real-time sensing across sewer, water and stormwater systems.

“If utilities are starting from scratch, this is an easy remote monitoring use case to start with,” said Trikoulis. “You’re automating a manual task, which makes the business case easy to stand up. Once the systems are in place, adding new use cases becomes much simpler.”

SA Water plans to double the number of monitored sites, using the data to inform broader asset planning and improve wastewater outcomes across the state.

Check out our solution page for more information on how septic tank monitoring works.